VisiPac

Full Digital and Compact Numerical Control for Press Brakes with 2D graphical profile drawing (Touch Profile) and 3D visualization

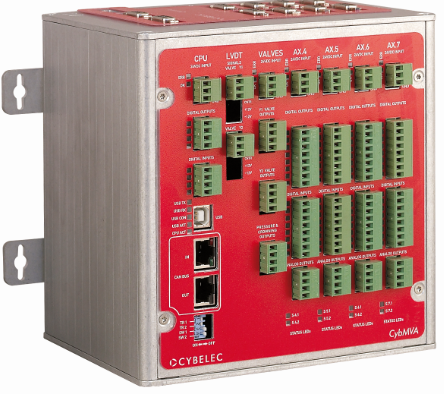

Modern compact CNC concept

- CNC mounted on the back of the screen

- Interface module in the cabinet

- Open software platform allowing customization

- 19’’ glass touch screen

Full digital concept

- EtherCAT and CANopen

- Windows 10 with power cut protection

- Industry 4.0 ready

User-friendly interface

- Intuitive programming in 2D and Numerical

- Touch Profile

- 3D viewers

call usnow

+91-9311082008

Features:-

Main Features For The User

- 19” modern streamlined glass surface touch screen that can be used with gloves

- User friendly HMI thanks to intuitive programming

- 2D graphic profile and 3D viewer

- Automatic bending sequence calculation

- All kinematics available

- – for X, Xrelatives, Xslave, R, Rslave and Z axes,

- – for Back and Front multiples gauges,

- – for bending aids

- Tandem

- Tools import

- Group management for complex production

- Preliminary / Final bend

- Hemming management

- Angle measurement

- Barcode reader

- Customizable, Industry 4.0

- Windows 10 for multitasking and networking

Main Features For The OEM

- Set up with dedicated wizards (auto-tuning)

- Axis control through CANopen® and EtherCAT® with wide configuration capabilities

- Customizable User buttons for the machine operator

- Interactions with the beam cycle

- Plug-in for HMI part

- Open system for customization, special crowning, hybrid hydraulic machine.

- Dynamic and regulated crowning cycles.

- Integrated robot control, synchronization with press brake sequences (robot CNC not necessary)

Options

- VisiTouch offline software (2D)

- VisiTouch MX offline software (3D)

- VisiTouch MXIMP offline software (3D + Import)

- Bending aids sheet support

- Automatic angle measurement

- Tandem management

- Robot communication and control

- Industry 4.0 data management